How to Adjust Saw Swing for Perfect Cuts?

In the world of woodworking, achieving perfect cuts is essential. One expert in the saw-swing field, John Fletcher, emphasizes, “A well-adjusted saw-swing is key to precision.” Understanding saw-swing adjustments can significantly enhance your cutting accuracy. However, this task often reveals our own shortcomings.

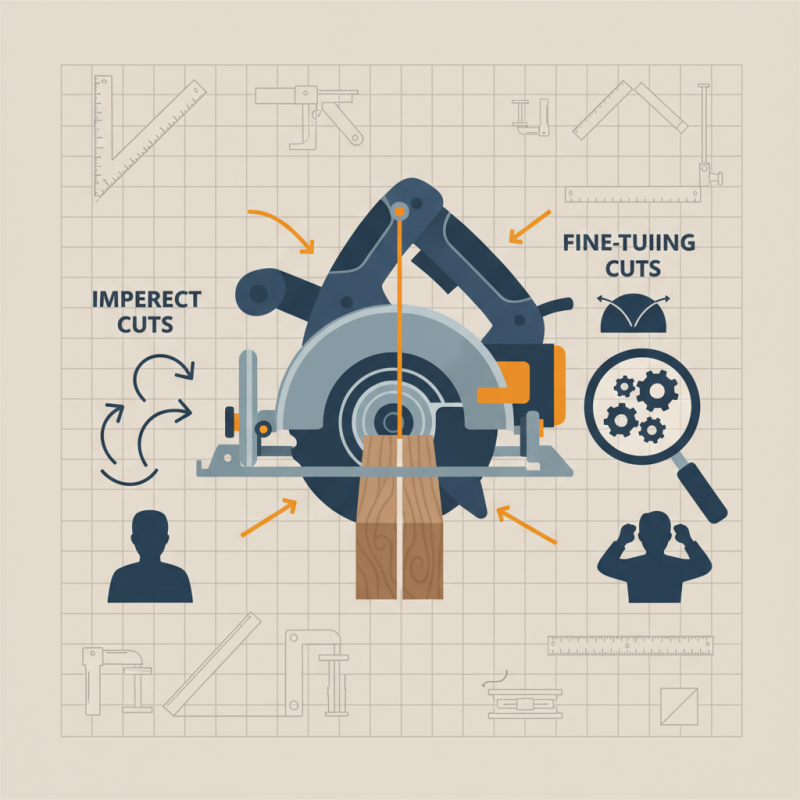

Consider how small misalignments lead to noticeable imperfections in your work. Even seasoned woodworkers miss the mark sometimes. Fine-tuning the saw-swing requires patience and practice. Ensuring each cut is straight can be challenging. Yet, reflecting on our technique may yield better results.

The process of adjusting the saw swing demands careful attention to detail. Small adjustments can create a big difference in your projects. It's easy to get frustrated when results aren't what we envisioned. But, refining our approach helps us grow. With determination, we can master the art of saw-swing adjustments for flawless cuts.

Understanding Saw Swing and Its Importance in Woodworking

Understanding saw swing is crucial for any woodworking project. Saw swing refers to the arc made by the saw blade as it moves through the material. This arc influences the accuracy of your cuts. If the saw swing is not adjusted correctly, it can lead to uneven edges or misalignments. These imperfections can disrupt the flow of a project. It also increases the time spent on corrections, which can be frustrating.

To achieve perfect cuts, focus on adjusting the saw swing before starting. Ensure your saw is calibrated properly. If it’s off even slightly, the end result may not be what you expected. Small mistakes in swing adjustment can lead to larger issues down the line. You might find that some cuts still don’t align perfectly, prompting you to reconsider your approach. The tension in the blade and the angle of the cut play significant roles in achieving the right swing.

Watch for signs of improper swing while cutting. If the blade wobbles or the cut feels rough, it’s time to reassess. Take the time to experiment with adjustments. Sometimes, the best learning happens through trial and error. Not every cut will be flawless, but with practice, you can refine your technique. Embrace the learning process; it's a vital part of woodworking.

Identifying the Correct Angle for Optimal Saw Swing

When adjusting saw swing, the angle plays a crucial role in achieving perfect cuts. A slight miscalibration can lead to uneven edges or misaligned joints. Begin by examining the cutting surface. If it’s rugged or inconsistently thick, this can affect the saw's performance. Adjusting your saw's angle to meet the material's requirement is essential.

Understanding the optimal saw swing angle can be a bit tricky. Many users set the angle without testing it on scrap material. This often leads to mistakes. Instead, take time to measure and adjust. Start with small changes. A 5-degree increment can make a significant difference. After adjustments, make a test cut. Check for smoothness and accuracy. Is it right? If not, reassess the angle. The goal is precision, not speed.

Remember, every project is a learning experience. Sometimes the angle feels right but doesn’t deliver. Reflect on your techniques and learn from errors. Each imperfect cut can guide you closer to mastery. Stay patient, and let the process teach you.

Adjusting the Saw Swing Mechanism: A Step-by-Step Guide

Adjusting the saw swing mechanism can significantly influence the accuracy of your cuts. To start, gather your necessary tools. You’ll need a wrench and a level. Review the manufacturer’s guidelines for the specific adjustments recommended for your saw type.

Begin by loosening the swing adjustment bolts. This will allow you to modify the swing angle easily. Use a level to check if the blade is parallel to the table surface. This step is crucial. Misalignment here could lead to uneven cuts or even splintering the material. Often, users overlook this detail. It’s important to take your time and be precise.

Next, gradually adjust the swing mechanism to achieve the desired angle. Tighten the bolts after adjustments but ensure you don’t over-tighten, as this can cause damage. Test the saw on scrap materials. It's okay if your first cut isn’t perfect. Learn from the mistakes. Fine-tuning your adjustments may be necessary. Remember, patience is key in achieving those flawless cuts.

Testing and Fine-Tuning Your Adjustments for Precision Cuts

Testing and fine-tuning saw swing adjustments is essential for achieving precision cuts. Many operators overlook the importance of swing settings, leading to poor cut accuracy. Research indicates that misalignment can reduce cutting efficiency by up to 30%. This inefficiency often results in wasted materials and increased operational costs.

To ensure optimal performance, start by checking the saw’s alignment. Use a calibrated square to examine the blade angle against the workpiece. Even a slight deviation can result in uneven cuts. Regularly measuring the gap between the blade and the guide is crucial. In some cases, users find discrepancies of over 1/8 inch, which can drastically affect the final product.

After adjustments, conduct test cuts on scrap material. Analyze the results closely. Look for uneven edges or burn marks, as these indicate a need for further tuning. Addressing these imperfections is key. Consider revisiting the swing settings if cuts are consistently off. Taking the time to refine these adjustments can drastically improve your workflow and final output quality.

Common Issues and Troubleshooting Techniques for Saw Swing Adjustment

Adjusting saw swing can be tricky. Many users face common issues that can affect their cuts. One frequent problem is misalignment. The saw may not swing evenly, leading to angled cuts. This can happen due to worn components or improper assembly. A quick inspection of the pivot points can reveal issues.

Another issue is excessive play in the swing arm. If the play is too much, it can result in choppy cuts. Tightening the screws may help. However, too much tightening can cause more problems. It's crucial to find that sweet spot for optimal performance. Inconsistent feed rates can also be a problem. When feeding the material too quickly, the saw may struggle to keep up.

Check the blade for dullness as well. A dull blade can lead to poor quality cuts, making it hard to determine if the swing is adjusted well. A clean and sharp blade improves cut quality. If adjustments aren't yielding results, consider the cutting technique. Reflect on the process and make small changes as needed.